Material excellence has always been one of the pillars of Wilfley’s success, solidified by a restless focus on operational longevity and optimized value. By contrast, many suppliers focus intently on reducing cost without consideration to increasing value. Unfortunately, a low initial price with increased ongoing costs favors the supplier, not the user.

One such example of Wilfley’s excellence and operational value is found in a large scale phosphoric acid plant. Conditioned to utilize the material of construction based on corrosion resistance alone, a very large producer in Western Asia originally mandated 904L (ASTM A743 Gr CN3M Mod / UNS N08904) for the metallurgy for their cake wash pumps.

Typical Phosphoric Acid Plant

The impurities and solids content in the “phos” acid were more aggressive and erosive than expected and made short work of the relatively soft 904L material, reducing the effective life of the pump to just 2-3 months. Based on nearly a century of heavy-duty pump experience, Wilfley recommended WCD4™: a specially processed duplex stainless steel (ASTM A890 Grade 1B / UNS 32550) with equivalent corrosion resistance but over 1600% increased wear resistance.

A year later, the Wilfley A7 pumps in WCD4™ construction are still running without requiring service, exceeding the plant manager’s expectations. The irrefutable operational success of Wilfley’s materials has fueled his efforts to convert to WCD4™ to fully realize the operational savings required in these difficult economic times.

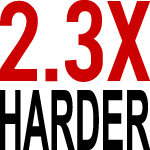

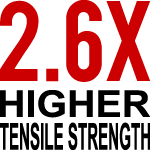

This astounding increase in service life can mostly be attributed to the improved mechanical properties of WCD4™ duplex stainless steel over standard 904L austenitic stainless steel. The hardness, tensile strength, and yield strength of WCD4™ all outweigh 904L by at least a factor of two, making it a much tougher material and far more suitable for pumping phosphoric acid. This is achieved through specially developed processes at Wilfley that alter the microstructure of the austenite and ferrite grains to optimize the mechanical properties.

WCD4™ vs 904L

345 HBN

164 ksi (1,130 MPa)

113 ksi (779 MPa)

When you look at the numbers, it’s easy to see the superiority of WCD4™ over commonly available stainless steel alloys. Wilfley has worked tirelessly over the years to develop breakthrough materials that truly add value to the customer and we’re definitely proud of this one.