The Model A9 heavy duty centrifugal pump is a proven design that provides extended mechanical seal life and maximum uptime and represents the culmination of nearly 90 years of continuous improvement in a chemical process handling equipment. A modern descendant of the ground-breaking Model AA released in 1929, the A9 meets or exceeds the requirements of ASME B73.1 specifications, yielding superior results for the lowest overall cost and highest uptime. Designed for continuous duty and high specific gravity fluids, it is truly engineered to deliver reliability and longevity for mission-critical services.

A9 Heavy Duty Chemical Pump

A Proven Design to Provide Extended Mechanical Seal

With multiple configurations available the Model A9 offers an ideal environment for all sealing options, especially the precision components used in mechanical seals. Available in oversized tapered and cylindrical designs, the robust A9 seal housing offers features proven to extend service life.

- Oversized taper seal housing is self-venting and removes heat build-up from seal faces

- Flow is recirculated in the seal area, removing solids and homogenizing two phase fluids

- Pressure balance holes transmit the lowest possible pressure to seal for reduced wear and seal drag

- Fluid is recirculated by pump out vanes to promote heat removal and solids expelling

Robust Shaft Design

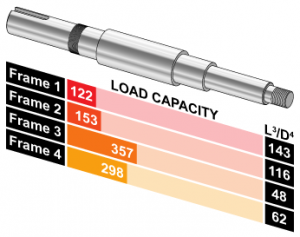

Wilfley designed the Model A9 with an incredibly stout power frame system that offers maximum precision and fortified positioning for single and double mechanical seals. This heavy duty design achieves industry dominating load capacity and L3/D4 values while still providing a sleeve to isolate the shaft from the pump fluid.

A9 Chemical Pump

Standard B73.1 Pump

- Scaled comparisons for sleeved shaft designs

- Process Industry Practices (PIP) recommends an L3/D4 of less than 75 for maximum seal life

- Load capacity is the maximum radial force (lbs) allowed without exceeding the ASME B73.1 shaft deflection limits (0.005″ at the impeller)

Heavy Duty Construction

- Scaled comparisons for sleeved shaft designs

- Process Industry Practices (PIP) recommends an L3/D4 of less than 75 for maximum seal life

- Load capacity is the maximum radial force (lbs) allowed without exceeding the ASME B73.1 shaft deflection limits (0.005″ at the impeller)